|

Scroll down through this Blog to see all the details of the Mini Cooper Restoration and reveal the full extent of the work carried out

0 Comments

Click this picture to take a look at some high resolution images of the finished Mini Cooper.

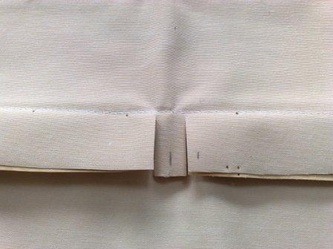

Many thanks go to my good friend Nick Bilsborrow for the awesome "launch quality" shots. So here I am, at the end of the project to restore the 1969 998cc Mini Cooper. It's taken rather longer than predicted, but that's down to other commitment on my behalf rather than too many un-expected findings on the car. In summary, the level of body shell re-construction was pretty major, and was the largest part of the work load. The Engine, Gearbox, Suspension and Interior were all pretty straight forward (apart from that brand new but faulty spark plug that sent me on a wild goose chase through the ignition system for a while!) There remain just couple of bits left to take you through, to make this a full and complete story! Reading back through the pages I have realised I did not cover the fitting of the boot seal, not the most exciting part, but worth a mention none the less, because it's a fiddly job and I don't know of anywhere on the internet that has pictures showing the orientation of the little clips. So here are a couple of shots to fill that gap! The new seal also resulted in the boot being very tight to shut. However with compression over time this has improved a lot. The last job to do before going out on the road was to fully set up the wheel alignment, on a Mini this is pretty straight forward. Only front tracking adjustment is readily available, however, after such a comprehensive restoration I always check all the parameters to make sure they are within the manufacturer specifications. In this case everything was spot on (a testament to the careful body restoration), however if adjustment would have been required there are various ways to compensate by adjusting the brackets that hold the suspension to the sub-frames. Below are the pictures of the car with the laser alignment equipment attached (not very "period" but it's the best equipment for accurate alignment). And that pretty much sums it all up! If you have any questions or would like to ask for any advice etc please do get in touch. The car is now up for sale, so again, please do get in touch if you're interested. There will be an E-Bay classified advert posted tomorrow.

I have some more High-Resolution pictures to upload very soon, I will update the blog when they are available. I have now turned my thoughts to the next project. There is a Golf Gearbox rebuild for a friend that I am already working on (I have pic's and will share them on here). But the next car-sized job I'm lining up is perhaps a little daunting, and definitely a "big one"! See if you can recognise it from the cryptic shots below. I have only taken a look so far, if all goes to plan, I hope to pick it up in a month or so. Then I can reveal all the details! As always, thanks for reading. Rob. I have just uploaded a few pictures of the finished car, Click Here to see them.

There are some more to follow and I will also finish the final part of the restoration story very soon Thanks! The last time I wrote about the interior the dashboard binnacle had just been wired and I had fitted the steering column, the next job was to fit the head lining. The original lining was badly torn and very tired so I sourced a new, original specification "Crinkle Effect" part. On the older cars Mk 1 and Mk 2, the head lining is attached to two frames that link in the middle on hooks, the later cars had a single piece lining on a wired frame. The first job was to strip the old fabric from the two frames and give them a clean. I then marked the center of the new lining and cut the retaining strips to clear the middle rib of the frame. I could then staple the retaining strips together to hold the lining to the frame, being careful to pull the fabric as tight as possible while fitting the staples. Next I removed a small section of the retaining strip near the edge, this allows the lining to pull up tight into the bends at the edge of the frame. The shape of the removed part is also shown in the first picture below. The edges and the front and rear require gluing with spray contact adhesive before being held in place with small clips, this is a fiddly operation as again it's important to pull the lining as tight as possible before fitting the clips, and it's also important not to get the glue on any of the visible surface. Once complete the second frame was re-covered in the same way and the finished part is refreshingly and bright and clean. With the new fabric in place it was time to fit the lining to the car. This is really very straight forward, it is simply pushed into place and is held by the ridge at the top of the body work. With the rear half in place the interior light could be fitted and wired and then the front section was pushed into place and linked to the rear using the hooks on the frame. With the lining in place I could then fit the trim-work round the rear window, this is in the same material as the rest of the lining and came as part of the replacement kit, although this being Mk 2 with the larger rear screen the side parts did need a little modification, but the edges all fit under the window rubbers so this did not present a problem. With all the trim in place round the rear screen, the next job was to fit the screen, which is the final piece in the puzzle to hold it all together. I like to use the "string" method for fitting screen rubbers, I know there are various techniques, but this one has always worked for me, although I use a length of washing line rather than string (the plastic coating helps prevent damage and it's a lot stronger than string. First I for the rubber to the glass, then I fit the line to the groove in the rubber that is going to fit to the body. I then place the assembly into the window aperture, and push it home along the lower edge. Up until this point it's all a bit of a balancing act, but once in this position it's all fairly stable and can be worked on carefully. By pulling the line from inside the car, it forces the rubber seal into place, it can be quite hard work at the corners and does require a few pushes from either side to make sure the glass is heading in the right direction. The pictures below show the job in progress. With the rubber and glass in place the final piece is the trim strip, this not only is the finishing touch for the eye, but it also expands the rubber to hold the screen tightly in place. The special tool is a must here, the first time I fitted a screen it took me about three hours and a whole lot of finger ache with a screw driver wrapped in cloth for protection. I then invested about £5 in the proper tool and it now takes about 10 minutes with no risk of damage! Once in place it's time for a cup of tea and a look at the finished job, from inside and outside! The next job is to fit the seats, and trim out the doors. The car came with freshly re-covered seats, so I don't have any work to do on them, and they are simple to fit. I now move onto the front screen, which means fitting the black vinyl trim on the interior, this was another Cooper feature, and would also have included black plastic surrounds for the screen vents (which I have yet to source). The vinyl trim is glued in place with contact adhesive and then held by the screen rubber and small metal clips under the dash board. The final operation to complete the interior is to fit the new carpet, this really sets it off and gives is a great "as new" feel.

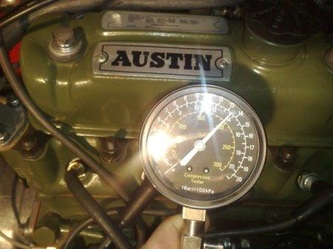

Well it's been a long time since I last updated the Blog, but that's kind of the nature of a project like this, it can be put on the back burner when other things take over. In fact the project has carried on, it's the blog updates that have suffered from the back burner treatment! So I plan to take you on a whistle stop tour of the last six months! I'll split it up into bite size chunks of Engine (firing up and tuning etc) - Interior (fitting out the "soft furnishings") and Body - (the satisfaction of adding all the bright work and shiny bits etc). But first to get the ball rolling, here are a few of the latest pictures, showing the finished article in all it's restored glory...  In the last Blog update the engine was just about ready to fire up, all that was left to do was a little plumbing, and that included the interior heater. This was in a bit of a state, fortunately only cosmetic, so a strip scrub and paint of all the components was necessary. I also air pressure checked the matrix using an air line and a bucket of water to make sure there were no leaks or weeps. Once the heater was fully restored the last of the cooling plumbing could be finished. So the time had come to crank the engine and see if it would come to life! The sequence for firing a fresh engine is quite critical. After filling with oil, I removed the spark plugs and spun the engine on the starter. Without the plugs there is no compression so the loads on the bearings, that are yet to be filled with pressurised oil, are as low as can be and the engine also spins a lot faster which gives the oil pump the best chance of sucking oil up from the sump During the engine build I had packed the new oil pump with grease to make sure it would have the best suction possible, and sure enough after a little while the sound of the engine turning changed, and the oil pressure gauge flicked into life. Stag one complete. I then carried out a compression check on all four cylinders, This is partly to make sure everything is working properly, but it also gives a reference value for each cylinder should there be any issues later. They are all nice and high (as you would expect with a newly honed block and freshly lapped valves etc), and also very nice and even across the cylinders. Stage three was to prime the fuel system, so the pump was connected, and at key-on that gave a satisfying click-click-click, until the pressure built up and the clicking slowed to a stop. A quick check all round for any leaks (fuel, coolant or oil) and we were ready for the big moment! Sure enough, a couple of cranks was all it took for the engine to fire, all be it a little rough, but it was enough to get it warm and carry out an initial timing check. Just as I was about to turn it off, there was a big hissing noise and some steam fom near the water pump! Not Good! I turned it off and an investigation revealed that the small hose between the water pump and cylinder head has burst along it's seam! (it was of course brand new, so I was very dissapointed it had failed on it's first use!). This would mean a Head-Off repair! A few explitlves, and about an hour and a half later the head was on the bench. I had left the spigot alone when rebuilding the head because they are notoriously difficult to remove, but it appears the route cause of the failure was the slightly eroded spigot, being shorter than it should have been the clamp had pinched the hose on the sharp end of the spigot, initiating the split (so my fault after all)!

Just to be sure I bought a silicon hose to replace it, not exactly original, but much stronger than the standard rubber part, and hidden from view once in the engine bay. I then went about the removal of the spigot. It was completely corroded in place, which meant it had to be drilled out and subsequently tapped to a larger than standard M16 thread. I made a new spigot on the lathe from an M16 bolt and secured it in place with thread sealant. Before re-fitting the head (using a fresh gasket of course). After following the same procedure again, the engine was back up an running once more. It took a fair amount of tuning and fiddling with the SU carbs (mixture, balance and engine speed), to finally see the car running smoothly. I finished all the other jobs, which I will cover in my next updates, but to finish the engine section i should tell you about the first test drive. Unfortunately this wasn't as smooth as it could / should have been, the engine was very hesitant under load, missing quite badly on one or two cylinders. I first tried a different coil, which had no effect, then I swapped the HT leads, also no effect, I then fitted a new distributor, which frustratingly also did not fix the problem (although it did make the off-load running spot on, and is now the correct part for this age of Mini Cooper). I finally decided to change the spark plugs (they were already new during the re-build), and that's what made the difference! It appears that two of the new plugs were breaking down under load, not something that I have ever come across before, and they were a good brand too? So finally I had the engine running as it should! Sweet through all speeds and loads, I have since traveled about 300 miles in the car to help bed in the bores and check for any little issues, but there has been nothing. So that was the engine story, next I will update you with the interior build, thanks for reading! Since my last post I have been busy working towards the day when the engine can be started, and there is not too far to go now. After refurbishing the Carburetors the next job was to refurbish and refit the front drive shafts and hubs. I had previously refurbished the hubs, they had required two new ball joints, new bearings and new discs, while the rest of the components had been stripped to bare metal and given a coat of rust preventing primer and engine enamel paint. So onto the drive shafts. After cleaning and dis-assembly I inspected the rubber components (drive donuts, and gaiters etc) for any signs of damage, dryness or cracking and was pleased to find that I only needed to replace the small inner boots. I then inspected the ball bearings, cages and housings for any pitting or polishing, and once again was pleased to find them all in excellent condition. So then it was a simple matter of fitting them all back together again with nice fresh grease. Next I inspected the dampers, they were working well when I drove the car home after buying it so it was a case of checking for leaks and with none found I went about cleaning and painting them. Finally I refurbished the brake calipers, the pistons were in good order but the outer dust seals were perished, so I bought a refurb kit and replaced all the seals, I have also replaced both the bleed nipples. I then gave them a coat of high temperature paint. Once complete, all the components could be fitted to the car (drive shafts, hubs dampers and calipers). This is one of those satisfying jobs that really makes a difference to the look and feel of the car, with hubs waiting for wheels it suddenly feels more like a whole car than a shell. I then carried out the same operation on the rear radius arms and hubs (not essential for the engine start, but it's much easier to fit the handbrake cables before the exhaust. They are all jobs that need to be done anyway. Unfortunately I have managed to corrupt the file of pictures showing the stripped parts and the rebuild, so below are the before and after shots. I replaced one wheel cylinder, the other was in very good condition, as were the brake shoes, I also replaced one bearing. The right hand hub nut thread was very stiff, so I have cleaned the thread on the stub axel and have ordered a new nut (it's worth noting that the hub nuts are handed, so the right one has a normal right hand thread, while the left has a left hand thread). I also fitted two new pivot pin kits which rather frustratingly were supplied with very slightly undersize plain bearings. After much deliberation, the fix was to borrow a reamer from my friendly local engine re-manufacturer and carefully resize the bearings. They were only 0.2mm under size and once machined went together perfectly. I've fitted a number of pin kits in the past and this was the first time I have needed to machine them to fit. The last two pictures above show the new Copper brake lines. I have included a protection sleeve, which is a length of thick plastic screen wash tube, slid over the Copper line before the end fittings are made. This gives a little extra protection, although not original and not essential, it's a technique I was taught when preparing cars for gravel rallying and it's very easy to do, so I tend to included it when ever I fit Copper lines near to the wheels. Next up I have fitted the fuel pump, being a Cooper this is a solid state electric pump fitted to the rear subframe (the non Cooper cars had mechanical pumps fitted to the back of the engine block that ran from an additional lobe on the Camshaft). That's as far as I have got at the back of the car, there is just the exhaust left to fit back here before the engine can be run. However there is still more work to be done elsewhere before that can happen. My next port of call is the interior, where there is some wiring to be done. I had previously rested the binnacle in place to see how it looked. Now it's time to make the wiring connections and fit it properly, quite a fiddly job, but by no means impossible. I also fit the steering column so I can wire the column stalk multi-plug (for the indicators, high beam and horn). I have managed to source an original steering wheel, although I'm still on the lookout for an "Austin" center, to replace the "Mini" one that came with it. So with all this sorted out and fitted the interior is really taking shape The last thing I have been up to is some plumbing and fitting out in the engine bay. I have run the heater hoses through the bulkhead, fitted new choke and heater valve cables, a new throttle cable and routed the speedo cable. As mentioned before, I'm trying not to use plastic cable ties, so where necessary I have secured the hoses etc by using lock wire, protected with a strip of flexile rubber sheet (actually it's cut from a surplus inner tube). So all that's left now, before the engine can fire, is a little more wiring, the heater needs to be refurbished, to complete the cooling circuit and the exhaust needs to be fitted! exciting indeed!

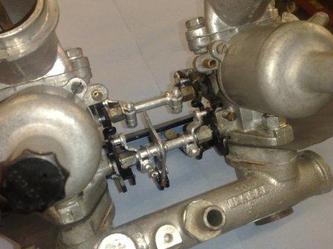

Finally for today I have taken delivery of a set of brand new reverse rims and tyres, so I'll leave you with a picture of them balanced in place. As always, until my next update, thanks for your time and good luck with your projects. Thanks for checking in on the blog, since my last update having installed the engine, I have had a week of holiday, but that doesn't mean there isn't plenty of Mini progress to update you with, far from it. The first job after fitting the engine meant changing the order of my plan round, for a very good but rather unexpected reason. Originally I was thinking I would finish off everything in the engine bay before tackling the rear subframe and rear suspension. However I noticed when lifting the car back up to a higher setting on the axel stands that with the engine in place and virtually no weight in the back of the shell, the whole car wasn't actually all that stable, there was a small risk that it could end up toppling forwards! So I brought the rear subframe strip and re-build forwards, literally to balance out the assembly.  Having used the rear subframe for alignment duties during the shell welding I knew it was in pretty good condition under the rather badly applied red paint, but once stripped it became clear that this is a virtually new part, it really couldn't have been any better. So all I needed to do was make sure it stays that way for years to come. As with the front subframe I first applied a coat of red-oxide primer, and followed this with a number of coats of hard wearing engine enamel paint, you can see in the pictures below that the headlamp bowls are also getting the same treatment. On a hot summer day it was like working in an oven and the coats were dry almost before I had finished. I then fitted the brake lines, the mounting brackets with new rubbers and the exhaust mounts before fitting it to the shell. Once in place the back of the car was nicely weighted down so I would be safe to continue my work at the front. So, back to the engine bay. First up is a strip clean and rebuild of the distributor, it goes without saying that I have fitted a new set of points, a condenser a Rotor arm and a cap, the leads were new on the car when I bought it, otherwise I would have fitted a set of those as a matter of course too. It's also important to check that the vacuum actuator is working, the rubber diaphragm inside can perish, but fortunately this one is fine and just needs a clean and a coat of paint. I then fit the Dynamo, as I have mentioned before the car was bought with an Alternator fitted, which was not the original specification for this period of car, so I have bought a new voltage regulator which is already fitted and this is a new dynamo. Then I have made a coil bracket to fit the coil in it's correct location above the Alternator, I did look but it proved impossible to find an original bracket, so mine is as close to original as I can get it, working from some pictures of old engines bays I found on the internet. Next up is a big job, in fact it took about twice as long as I was anticipating, the Carburetor rebuild. It only took longer than expected because I had forgotten just how many components there are in the carbs and they all need to be cleaned and made spotless. Plus of course, being a Mini Cooper there is a pair of them! So I had a happy couple of evenings in the degreasing tank (affectionately named the "Gunge Tank" by my daughter!). There are some parts that can wear on the SU Mini carbs, the needle and jet are examples. However it’s very difficult to measure, and almost impossible to see needle and jet wear, so I have rebuilt using the original parts and will wait to assess their condition when the engine is running. With a running engine it will be apparent if there is wear (to be honest it was running quite well when I bought it so I don't expect to have an issue). I did however find significant wear on one of the throttle plate spindles, so I sourced a replacement, which came in a kit with new throttle plate screws directly from SU. Its worth passing on that SU are still in business and still sell spare parts in kits for their original products, which for the spindle I needed, was the cheapest I found (SU is actually part of Burlen Fuel Systems now, but they can be found under SU on the web). As you can see in the pictures above I tackled one Carburetor at a time, even having stripped and rebuilt numerous of these, it's still worth restoring them individually, initially this is a good idea because you always have a fully assembled part for reference, but the main reason I do it this way is to make sure I don't mix up the parts for one side into the other and vice versa. It's important to put the same components back together in the place they came from because they will have bedded in there, and you will get unwanted clearance and / or faster wear if you don't put them back into their original location. Once complete it's time to put them back onto the engine, which also secures the exhaust manifold into place. So it's all coming together. I have also rebuilt the drive-shafts and front hubs, but I'll take you through that in the next blog.

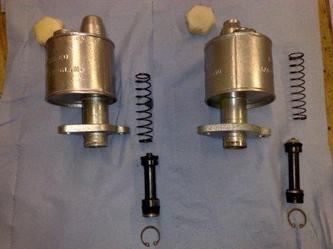

Thanks as always, for your time. Before I sign off I should let you know that the car is now advertised on E-bay. My plan is to have it finished by the end of September, so the advert will hopefully create some interest ahead of that. After all, the sooner it sells the sooner I can start the process of looking for the next project! (However for now, this one is getting very exciting!) This is the good bit, the part I really enjoy, Reassembly. It's started in ernest and I can start to see the fruits of my labour. All those hours in the cleaning tank, the endless wire brushing, the carefull painting of parts is finally paying off. It's also satifying fitting parts and knowing, for that little component, however small, the job is done (and its no longer occupying the space on the bench which it has called home for the last few months!)  So to business. The first parts to be fitted to the new shell are the door straps, this is a protection measure to make sure the doors aren't opened too far, which could damage the painted hinges, I then fit the door seals, again to protect the fresh shiny paint. The first proper assembly job is to run the wiring loom through the shell. For this project I have spoilt myself and bought a brand new loom from Mini Spares. This is partly to save time, the old loom had been badly cut and shut to run an alternator instead of the correct dynamo, but it's also because there is nothing better than new wiring, it makes sure there are no niggling continuity issues, no corroded terminals, and no cracked or broken wires hidden deep inside, plus specifying a period fabric wrapped loom it's going to look fantastic as well. Because of the dodgy alternator, there was no voltage regulator in the car when I picked it up, so I have a shiny new one of those (and a dynamo to fit to the engine later). I also fit the fuse box, and because the wires are run with the wiper mechanism, I have stripped cleaned, painted, restored and fitted the wiper motor and mechanism too. My enthusiasm also got the better of me and I have rested the dashboard in place to see how it looks, which explains the white tube in the pictures, it's the capillary tube for the oil pressure gauge, and I couldn't resist fitting the new wing mirrors too! Now I'm motoring. The next major job is to restore the brake and clutch master cylinders, (including a seal kit for both). I'm very please that under the grime they are both in very good condition. Once fitted to the bulkhead, which includes fitting the peddle box inside, I run the copper brake and fuel lines all the way under the car. This is all heading in the direction of the engine fit, the brake and fuel lines both run behind the front subframe so need to be in place first. Another component that needs to be fitted before the engine and subframe is the steering rack, having already been restored this is very simple, but even if I say so myself, it looks great once in place. I also fit a few more chrome parts, and it's really starting to look like a mini again!  One thing I am very keen to do, is keep this car as original as possible / practical. To this end I have decided not to use cable ties where they can be seen. A friend once said he simply couldn't go rallying without a bunch of cable ties and a roll of gaffer tape "what on earth did they do in the old days?". The answer lies in clips and lock wire! So here on the brake and clutch tubes I have used two protective lengths of washer tube and some neat lockwire to stop the copper pipes tizzing. For sure it's a little more time consuming than a cable tie, but I hope you will agree, it's a much "more period" result?  There are just a few more parts to fit to the bulkhead before I can get the engine ready for fitting. The washer bottle and hoses go in, as do the bonnet hinges, and there we are, ready to receive the front subframe and engine! So now I have a little prep work to do away from the body. I need to fit the engine into the subframe, but even before that I have to fit the front brake lines. A job that can't easily be done once the engine is on place. I then fit the gear change mechanism, being a Mk2 Cooper this is car has a "Remote" type change, the "Non-Cooper" of this age would have had the "magic wand" type gear leave, and the body shell still carries the hole for this type, but here it will get a blanking plate. Now it's time to fit the engine into the subframe, a careful operation, and to be honest a little fiddly, especially fitting the left hand engine mount bolts with the radiator in place. Once complete the whole thing can be wheeled to the body. And so to the final "decking" of the engine and subframe assembly. With the back of the car supported as low as possible on axel stands, I lift the front of the car high enough to roll the engine assembly under the front. I then carefully and slowly lower the body checking to make sure everything is clear and roughly in the right alignment. Once the body is lowered back onto the axel stands at the front (which have been set to the same height as the rear stands). I lift the engine and subframe the final few inches into place with a crane. The alignment at this point is critical, but it can be controlled by dropping a bar down through the body fixing points on the bulkhead into the top of the subframe suspension towers, thus giving an effective leaver to move the few millimeters when necessary. Then it's time to fit nuts and bolts to hold it all in place, before a well deserved cup of tea and a chance to take stock (and a few more pictures of the engine in it's rightful home). That brings you up to date. Next up is the remaining engine bay fitting out (dynamo, distributor, carburetors, wiring etc etc). So until then, thanks for your interest and your time, and good luck with your projects, whatever they may be!

Now the body shell is back from the paint shop I'm getting excited about the prospect of starting the re-assembly process, however before I can get carriend away there is some more restoration required. First up is the Front Subframe. Fortunately this is in remarkably good condition and will only need stripping, rust protecting and painting, here are some pictures of it all stripped down.  All the other components receive much the same treatment, and where necessary I have replaced parts with new components. In this layout picture you can see I have new ball joints and brake discs, I'll also fit new wheel bearings and rubber bushes as a mater of course. The hubs, drive flanges and back plates (once stripped and re-painted with tough engine enamel paint), are ready to be used again, hopefully they will last another 41 years! Here's something that you might not know. It's fairly common knowledge that the early Mini Coopers and Cooper S cars were fitted with front discs, in place of the standard cars front drum brakes. What you might not know is that on the Mk1 and Mk1 two cars the Cooper discs were 7" diameter while those on the Cooper S were 7 1/2" parts. From Mk3 all the Coopers (whether S or not) used the 7 1/2" set up. This means that the 7" parts are getting quite difficult to find and it's not just the discs that are unique, the calipers, brake pads and drive flanges are all matched to the 7" specification. Once all the parts are ready I can fit the suspension and brake lines back into the subframe. I have left the hubs off for the moment because it's mich easier to handle the subframe assembly without them, so they will be fitted after the subframe is in the car. Next for attention is the steering rack, I follow much the same process as the subframe, but on the rack there are some measurements to make to ensure the right shims are fitted, and the running clearance is to specification once it's re-assembled.

Below are the "before" pictures, unfortunately the "during" and "after" pictures have been corrupted, so you'll have to wait to see just how nice and shiny I have managed to make it! The next job I’m really looking forward to.... a chance to start fitting parts to the fresh body shell. |

AuthorRob Russell. Archives

May 2012

Categories

All

Click to follow the Blog on Twitter

|

RSS Feed

RSS Feed