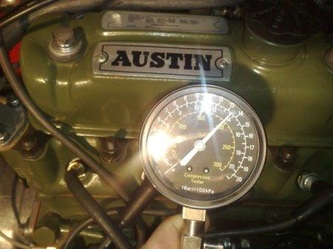

Click this picture to take a look at some high resolution images of the finished Mini Cooper.

Many thanks go to my good friend Nick Bilsborrow for the awesome "launch quality" shots.

Many thanks go to my good friend Nick Bilsborrow for the awesome "launch quality" shots.

RSS Feed

RSS Feed