Hi Thanks, for checking out my blog that's covering the "Bulkhead Forwards" restoration of my Peugeot 205 1.9 GTI.

In my last update I had the engine installed and running and had just completed a first run, all-be-it about 30 yards out and back into the garage, with no bonnet, wings or bumper!

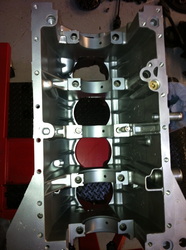

For details of the engine build and to see the extent of the work I have carried out, just scroll down and you'll be taken through the blog history.

In my last update I had the engine installed and running and had just completed a first run, all-be-it about 30 yards out and back into the garage, with no bonnet, wings or bumper!

For details of the engine build and to see the extent of the work I have carried out, just scroll down and you'll be taken through the blog history.

After a little wait, the bonnet, wings, bumper and grill are ready for collection. I decided to add some Peugeot Talbot Sport stripes to the grill, in a little ode to my rally hero Ari Vatanen who wore simila stripes on his Pikes Peak conquering 405 T16!

So obviously the next job was to fit all the lovely shiny white bits to the car, taking care to position them with the best possible panel gaps.

And there it is - all back together. I'm particularly happy with the paint match. The colour is "Alpine White", but both the paint shop and I weren’t happy with the look of either the "new" or "aged" paint cards, so they had a section of the original paint "electro-optically" scanned, which defined the exact mix and like I say, I'm happy to report has given a perfect match - time will tell how the two paints age from here.

So it's time to look back and do a little "Before and After" comparison.

So it's time to look back and do a little "Before and After" comparison.

Here's another comparison that I'm particularly proud of, on the left is the engine bay of a 25,000 mile mint 205 GTI recently sold by 4 Star Classics, they have a great knack of finding some of the very best examples of some fantastic classic cars. On the right is my version!

Finally here are a few shots taken during one of the first outings by my good friend and good photographer Nick Bilsborrow. (No I'm afraid I can't take the credit for the "road markings!")

There we are! Another project ticked off! I have to say it's been a really pleasurable one to work on.

Thanks for your time interest.

Rob.

Thanks for your time interest.

Rob.

RSS Feed

RSS Feed