Having stripped the whole engine to basic components, the first job is always to clean and inspect everything, some of this is done visually, as with the bearings, and some is done by measurement, the rings, thrust washers and crank journals etc.

What I found was the engine was in basically very good condition for it's age (approx 90,000 miles), but the various components that are designed to wear over time were all at least half way through their usefull life, and so, for this to be a comprehensive re-build, to last the car for another lifetime, those parts needed to be replaced.

So the crank, pistons, rods, piston liners, block, head, valves and the drive sprockets were all perfectly capable of being reused. The bearing liners (big end and mains), rings, every seal and gasket and the drive belts, along with most of the external hoses, and other servicable items, water-pump, thermostat etc all had to be replaced.

While carrying out the process of finding the most cost effective sources for all the parts, I degreased all the Aluminium parts and sent them away for Aqua Blasting, the results of which i have to say surpassed my expectation.

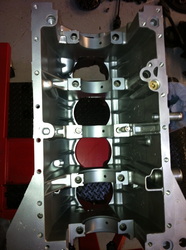

Here's the Cylinder Block "Before" and "After" Pictures

Well almost, it also uncovered a little bit of corrosion on the head flame face - if you click on the 2nd pick to enlarg it, you can see what i mean - some of the damage was very close to the gasket sealing beads, so I decided to take the cautious approach and have the head skimmed. I only had a minimum amount of metal removed (0.2mm) so as not to increase the compression ratio significantly.

A compression ratio increase allows the engine to run with a more advance spark for increased power, but this goes hand in hand with the need to run higher octane fuel. My plan is to have the car as a daily driver, so I didn't wish to go down the "tuned" route at the expense of having to fill the car with Super all the time.

Once the Ally parts returned from cleaning, it was time for re-assembly to begin in ernest.

One part that has a bad reputation on 205 GTI ("XU") engines (both 1.6 and 1.9), is the very small section 'o' rings that seal the bottom of the liner into the block. These are very critical as a failure will see all the coolant leaking from the block water jacket into the oil sump, and the first time you will know it's happened will either be when the engine overheats through lack of coolant or when the bearings destroy themselves because they are being lubricated by an emulsified mess of mixed oil and coolant. They are notorious for leaking after major engine work, but that's almost always because the work has been done while trying not to disturb the liners or the seals, once disturbed it's impossible to know if the o'rings have broken or if some dirt has gone across the seal. So I would have to advise that it's much better to bite the bullet and remove the liners, do a very thorough job of cleaning everything, and ALWAYS build with new 'o' rings. I help the initial seal, and help hold them in place on the liner with a light smear of LM grease. Using these rules and this method I have not had a problem.

In the Pictures below you can also see the process of checking the gap dimension on the new piston rings, if they are too tight they can be adjusted by carefully filing the ends with a needle file, fortunately for me all the new parts were inside the spec limits.

Valve lapping is simply the process for 're-seating' the valves into the head to make sure they seal the combustion chamber perfectly. A grinding paste is added between the valve and the seat and the valve is rotated to grind the seat and valve into a matched pair.

In the right hand picture below you can also see the head face after the skimming process, there is still some evidence of corrosion damage but now it's nowhere near the gasket sealing bead paths.

Having had such a great result with the Aluminimum Aqua Blasting, I went down the road of having all the steel parts shot-blasted and powder-coated, which set them off a treat too.

Thanks as always for you time!

RSS Feed

RSS Feed